/timing-belt-honda-56a055553df78cafdaa10fe0.jpg)

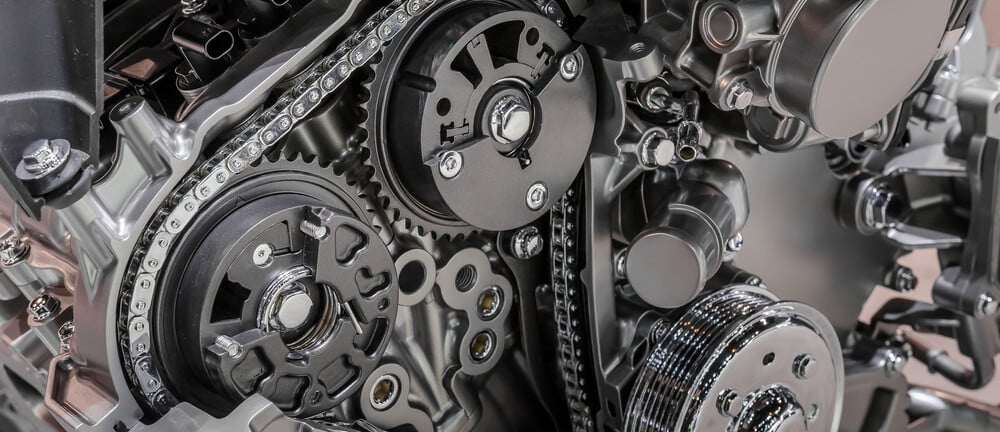

If you have the heads off the engine for any reason, or if you are overhauling the engine, you should also replace the timing belt, chain or cam gears. On newer engines, the original equipment belts are made of better materials and typically have a recommended replacement interval of 100,000 miles or more. For mid-1990s and older engines, the recommended replacement interval for most timing belts is usually 60,000 miles. The best time for a vehicle owner to replace a timing belt or chain is before it fails. The engine may continue to run but will experience a loss of performance because of the altered valve timing. Interference engines include most Japanese and European engines as well as Chevrolet 1.5L and 3.4L 1995 Chrysler 2.0L and 2.5L 1997 and newer Chrysler 3.2L and 3.5L and Ford Probe 2.0L and 2.2L engines.Ī timing chain or belt may also jump time if it is loose. A cam drive failure can also cause expensive valve damage in “interference” engines that don’t have enough clearance to prevent the valves from hitting the pistons if the cam stops turning or jumps out of time. If a timing belt or chain breaks, or the cam drive gears fail, the cam stops turning, the engine loses all compression and the engine stops running. But they do stretch as they age, which can cause rubbing noise and retarded valve timing. Timing chains, by comparison, are mostly immune to the effects of heat. The cords inside the belt also weaken as the belt accumulates wear, increasing the risk of the belt breaking. Over time, this causes the rubber to lose flexibility, harden and crack. As a belt wraps around and turns the sprockets, friction creates heat (this is in addition to the heat from the engine itself). That’s why belts are used on many OHC engines. While chains are more durable than belts and typically have a longer service life, they are also heavier, noisier and more costly to replace. Chains are made of steel links connected by flexible rollers.

Belts are made of synthetic rubber reinforced with tough fiber cords that provide tensile strength and prevent the belt from stretching.

They have to turn the cam with enough force to overcome the resistance of all the valve springs. Timing belts and chains carry a heavy load. You can replace the timing belts for preventive maintenance, and you can replace the timing chain if it has stretched or is worn. This type of setup doubles your opportunity to service the cam drive system. Chevy’s 3.4L DOHC V6, for example, uses a timing chain to drive an intermediate sprocket that also drives two belts (one for each pair of overhead cams). On some engines, the valvetrain uses both types of drives: a timing chain and a pair of belts.

0 kommentar(er)

0 kommentar(er)