It’s a water-based system, so you don’t have to worry about fumes disrupting your tenants.It’s economical, which means you can build it up to the correct thickness you need without wasting extra money.

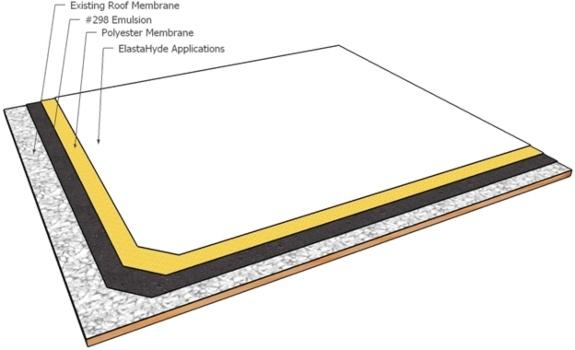

There are many advantages to using asphalt emulsion systems. When you combined its waterproofing properties with strength of a polyester membrane and high emissivity and reflectivity of the energy efficient acrylic topcoats, such as Western Colloid’s #720 ARC ElastaHyde, the systems may also improve your building’s energy efficiency. It also saves materials by utilizing your failing roof system as a base and saving landfills from additional waste. It’s economical in nature, making it affordable to build up a membrane of sufficient thickness to stabilize most existing roof substrates. The primary use of Western Colloid #298 asphalt emulsion roof coating is as a waterproofing compound for existing built-up, BUR roofs, Modified Bitumen, Coal Tar Pitch, TPO, EPDM, Hypalon and Gravel roofs that saves you from tearing off your existing roof. It effectively seals all cracks and seams in your existing roofing system. Western Colloid’s #298 asphalt emulsion roof coating is non-flammable, non-fibrous and virtually odorless. The emulsifying process breaks down the molecule size, resulting in a stable waterproofing compound.

Western Colloid #298 asphalt emulsion consists of asphalt, bentonite clay and water which are emulsified utilizing a colloid mill. Most of the Western Colloid asphalt emulsion based systems have FM 4470 Class 1 approvals, ensuring that these systems have been tested by the highest standards for durability. Plus, they are compatible with most other roofing membranes and coatings. Not only will it extend the longevity of your roof, but it can also easily be applied to a number of existing roof systems. If you’re looking for a strong, waterproof and long-lasting architectural roof coating system, an asphalt emulsion based coating system is a great option.

0 kommentar(er)

0 kommentar(er)